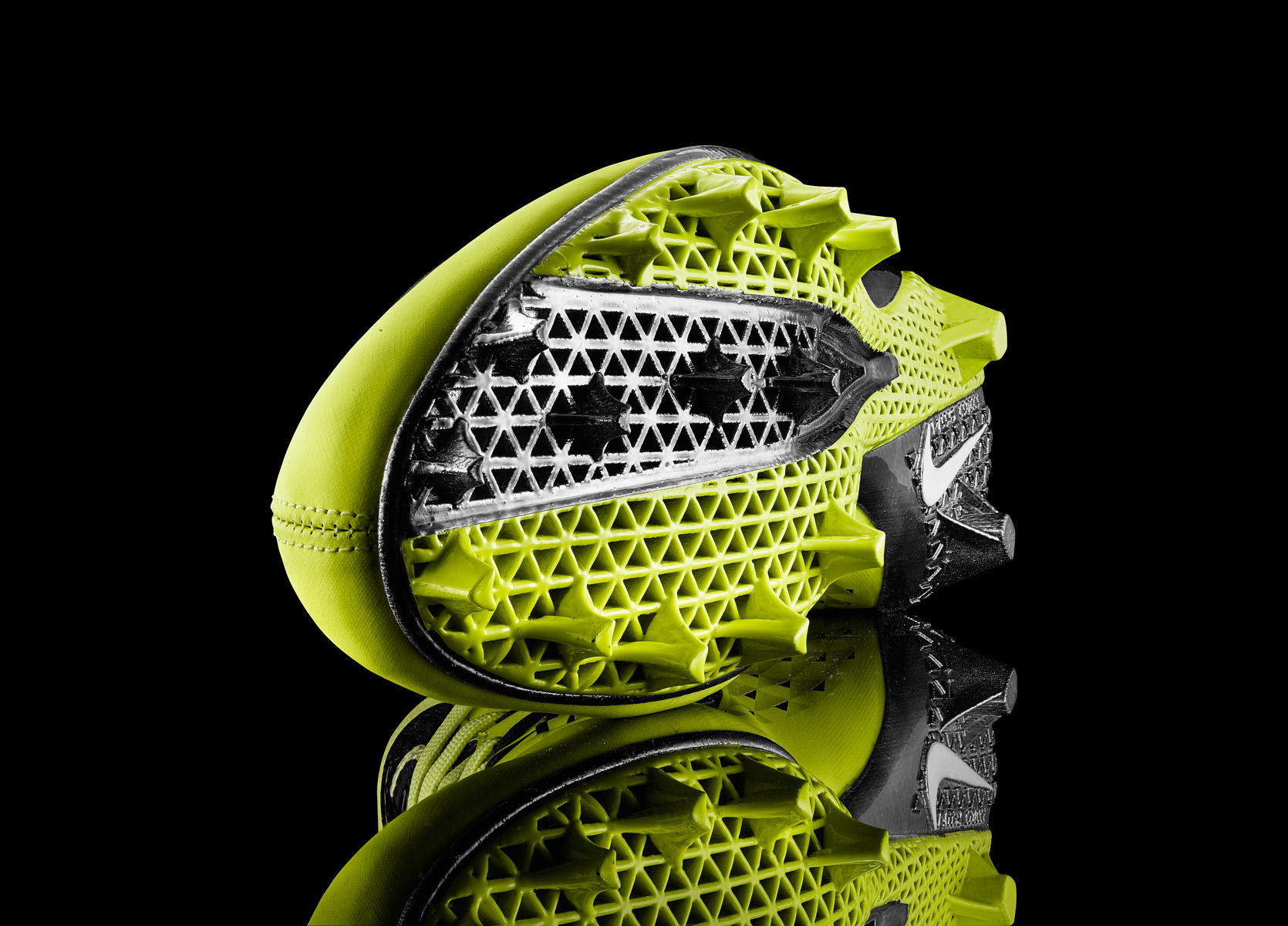

THE NIKE VAPOR LASER TALON; INTRODUCING SLS TECHNOLOGY

Although not a football item per se, the Nike Vapor Laser Talons offer a glimpse into the future of how football boots, and perhaps many other objects we take for granted, will be made. Designed for American football rather than soccer, the boots/cleats have been manufactured using the latest 3D printing techniques.

The plate of the cleat is crafted using Selective Laser Sintering technology (SLS). It is the sport’s first 3D-printed plate. SLS is a manufacturing technique that uses high-powered lasers to fuse small particles of materials into a three-dimentional shape. Through proprietary material selection, Nike was able to prototype a fully functional plate and traction system within a fraction of the traditional timeframe and at a fraction of the weight. The SLS process allows for the engineering and creation of shapes not possible in traditional manufacturing processes. It also provides the ability to make design updates within hours instead of months to truly accelerate the innovation process to never seen before speeds.

“SLS technology has revolutionized the way we design cleat plates – even beyond football – and gives Nike the ability to create solutions that were not possible within the constraints of traditional manufacturing processes,” said Shane Kohatsu, Director of Nike Footwear Innovation.